product presentation

High speed steel roller maintain high hardness and wear resistance at high temperatures. Produced by centrifugal casting, the core is made of ductile iron, and the working layer hardness reaches 80–85 HSC. The martensitic matrix is distributed with vanadium, tungsten, niobium, and molybdenum composite carbides, ensuring uniform hardness in the working layer and even hole pattern wear. Mainly used in finishing mill stands, they can extend operation time and improve the surface quality of rolled products.

Product Parameters

Size | Ф200mm≤body diametr≤Ф800mm | |

Mill stand | Section mills | |

H-shaped mills | ||

Wire & rod mills | Pre Finished,Finished | |

Strip mills | Finished | |

Chemical Composition

Material | C% | Si% | Mn% | W% | V% | Ni% | Cr% | Mo% | Mg% |

HSS | 1.6-2.0 | 0.20-1.00 | 0.30-1.00 | 1.50-2.50 | 4.00-6.00 | 0.50-1.50 | 4.00-8.00 | 4.00-6.00 | 0.50-1.50 |

Performance and application

Mark | Hardness(HS) | tensile strength(Mpa) | purpose |

HSS | 80-85 | ≥700 | Hot roll strip/cold roll strip/bar wire rolling |

applied range

High speed steel rollers have the advantages of high hardness, good wear resistance and strong thermal stability, so they are widely used in the field of steel rolling

Packing and shipping

Mainly using iron bracket and wooden box packaging.

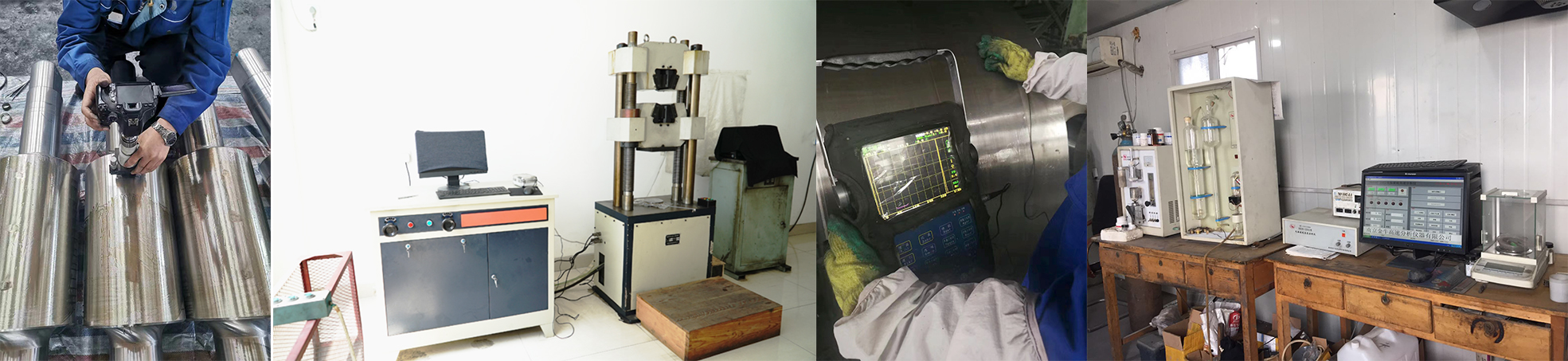

Product Quality Inspection

Our products will be flaw detection, spectrometer, hardness, finish, water pressure test.

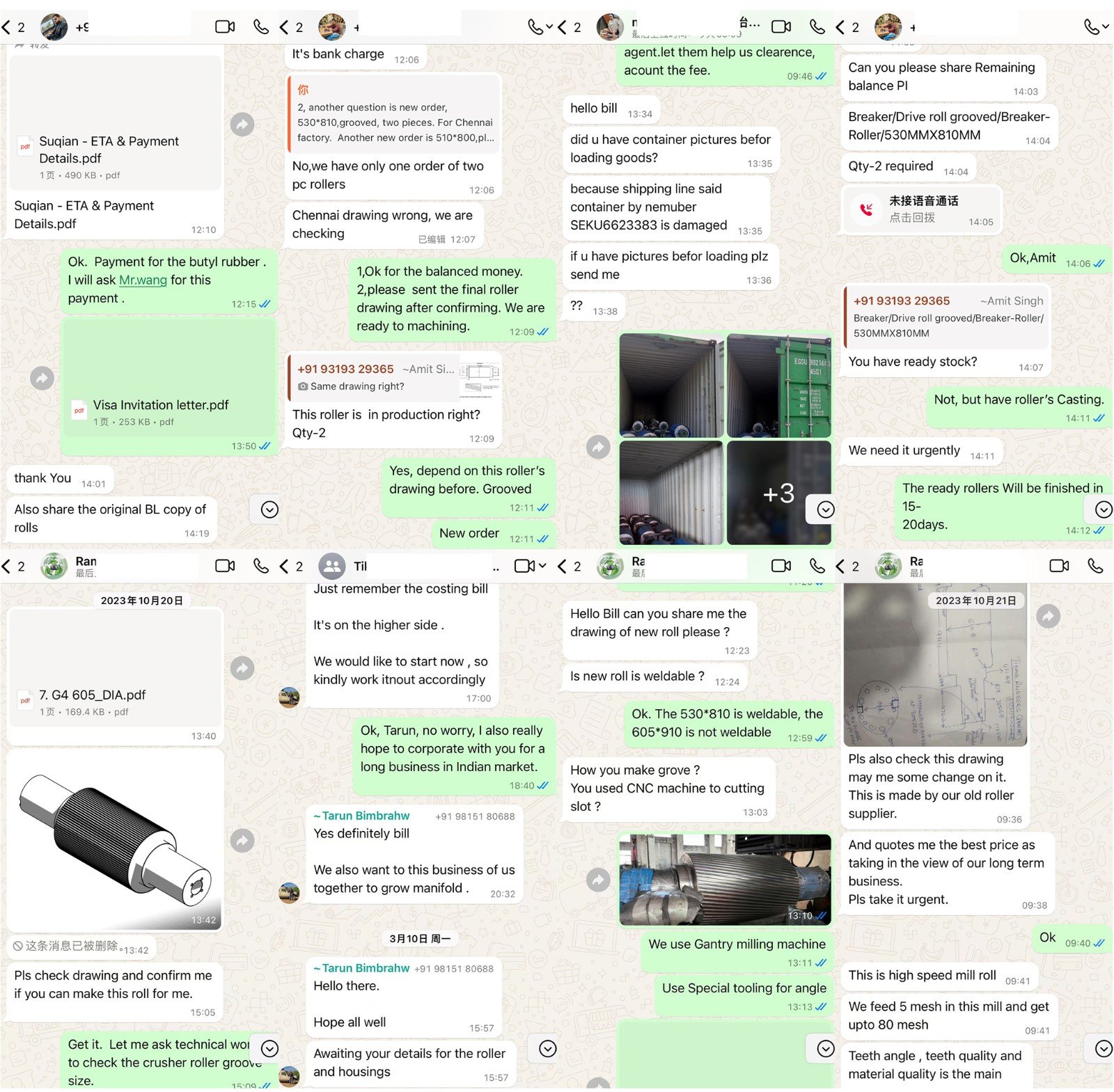

customer feedback

Since establishment , we have been committed to becoming a famous roller supplier , vigorously developed overseas markets, and successively supplied rollers to customers in Philippines, India, Egypt, Russia, South Korea,Vietnam, Turkey and other countries.

client

corporate information

Qingdao XinShengYuan Roller Co.,Ltd has been specialized in producing all kinds of mill rolls and their parts since 2009. Our products are widely used in iron and steel metallurgy mill, rubber mill, grain mill, paper mill and other occasions and fields. Our products are reliable and long-lasting, backed by 15 years of experience. 50% of our products are exported all over the world. By leveraging our hard-earned reputation, honesty, reliability and quality, Qingdao Xinshengyuan Roll Co., Ltd aims to continue as a pioneer in sales. At the same time, we are looking for global partners overseas. If you are an end user, distributor or agent of all types of mill rolls, please contact us. We look forward to working with you in the near future.

our advantages

1. We have 15000 square meters of modern processing and casting workshop, with environmental protection production procedures of the Chinese government,can be timely and stable production and supply.

2.With imported metal spectrum detector, ultrasonic flaw detector, metallographic detector, hardness detector, finish detector and other advanced testing equipment, with advanced mill roll quality control process, to ensure that the technical parameters of mill roll meet the certification requirements of international customers.

3.Our company adopts the world's advanced centrifugal compound casting technology, which can obtain the advantages of high hardness, anti-wear,and thermal fatigue resistance, greatly extending the working life of the mill roll.

FAQ

1.Are you a factory or a trading company?

Factory.

2.How do i order?

Buyer sends the enquiry --> Buyer gets the quotation --> Order confirmation --> Buyer send the deposit --> Seller prepares goods --> Seller makes the strict inspection --> Buyer Arranges Balance Payment --> packing and delivery.

3.How long is the delivery time?

Depending on the number of roll's order, delivery time is generally 30 to 90 days.

4.How to confirm payment?

We accept wire transfer, paypal payment, other payment methods are also acceptable, please contact us before you pay through other payment methods. In addition, a deposit of 30% is feasible and the balance should be paid before shipment.

5.Our Service

If the roller breaks and other quality problems occur during the shelf life, we will unconditionally replace the new roller.